Pneumatic membrane systems can produce self-forming structures using air pressure from 2D patterns that can be used as lightweight formwork for concrete structures and building components. This project explores several methods for adopting pneumatic structures as the formwork for GFRC (Glass Fiber Reinforced Concrete) construction. By combining large air volumes and surface patterns we can reduce material waste in the creation of complex geometry formwork and small to medium scale architectural elements. The research explores two primary methods of GFRC fabrication using lightweight pneumatic formwork, casting into welded patterns over a large pressurized air volume and spray forming over self-forming inflatable structures with localized pneumatic support systems. The first method produces open lightweight structures in a variety of complex forms, the second method produces thin shells that follow form-active structural logic. The methods can be combined to address larger or more complex formal and structural applications. This phase of the project has developed several techniques and opportunities through small to medium-scale prototypes that could serve as large working models for architecture or as architectural paneling systems.

Funding for this research has been provided by Pratt's Faculty Development Fund and the Architecture League of New York's Independent Projects Grant and the New York State Council on the Arts.

Super Lightweight: 2D CNC Welded Patterns for Self-Forming 3D Pneumatic Formwork for GFRC Fabrication

Robert Lee Brackett III

Duks Koschitz

Research Assitants:

Weiting Sheng

Hannah Bacsoka

Abby Lo Presti

Shira Saar

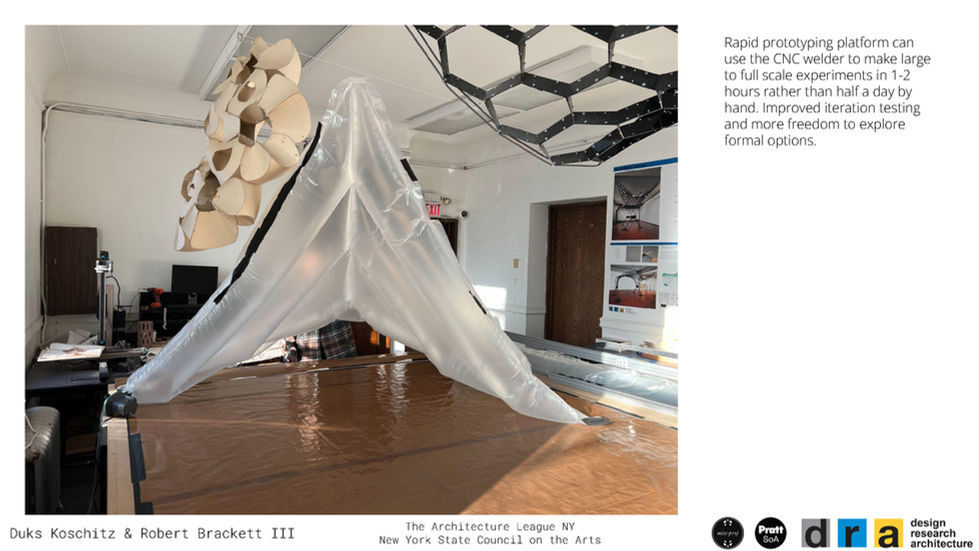

The project investigates 2D patterns for welding two sheets of Polyethylene (HDPE) together using a custom-built CNC (Computer Numerical Control) machine to produce 3D self-forming pneumatic hypar structures. The hypothesis is that these lightweight and materially efficient structures can use air pressure to support a complex formwork for casting and spraying GFRC (Glass Fiber Reinforced Concrete) shells and grids to produce architectural components and small-scale structures. The current research period and support by the ALNY (Architecture League of New York) Independent Projects Grant provided funding to upgrade and refine the custom-built CNC machine for faster and more repeatable medium to large-scale testing of self-forming structures, materials for testing casting and spraying, and funds for documenting the installation of the Pop Up Drop Off inflatable pavilion at various research and environmentally focused events. The primary outcomes are large architectural model scale speculations using pneumatic formwork for GFRC, architectural panel scale proof of concept prototypes using spray GFRC over pneumatic formwork, and a broad body of references and experimental techniques and methods for producing super lightweight pneumatic formwork. The next step is refining details for fabricating furniture and panel-scale GFRC prototypes to test full-scale applications and compiling the findings into research papers and conference presentations.

The d.r.a. believes in ‘sustainable geometry’, which uses concepts in geometry and material corollaries to create lightweight and low-carbon construction methods. We design and make projects that are exhibited to make the general public aware of sustainability issues, such as lowering the carbon footprint for the built environment and plastic waste. This proposal investigates inflatable hyperbolic paraboloid (hypar) structures and their potential as lightweight formwork for concrete.

Inflatable structures can support large volumes of space efficiently by leveraging the surface tension of a membrane material. Pneumatic membrane systems can produce self-forming structures using air pressure from 2D patterns that can be used as lightweight formwork for concrete structures and building components. This project explores several methods for adopting pneumatic structures as the formwork for GFRC (Glass Fiber Reinforced Concrete) construction. By combining large air volumes and surface patterns we can reduce material waste in the creation of complex geometry formwork and small to medium scale architectural elements. The research explores two primary methods of GFRC fabrication using lightweight pneumatic formwork, casting into welded patterns over a large pressurized air volume and spray forming over self-forming inflatable structures with localized pneumatic support systems. The first method produces open lightweight structures in a variety of complex forms, the second method produces thin shells that follow form-active structural logic. The methods can be combined to address larger or more complex formal and structural applications. This phase of the project has developed several techniques and opportunities through small to medium-scale prototypes that could serve as large working models for architecture or as architectural paneling systems.

d.r.a. Lab research into self-forming 2D patterns that create 3D pneumatic structures that can be used as formwork for concrete casting was presented at the 2023 Pratt Research Open House in the Pratt Research Yard. Funding for the materials and equipment was provided by Pratt's Faculty Development Fund and the Architecture League and the NYSCA.

ALNY + NYSCA Independent Project Grant 2023 Funds

Materials: $4,000

$1100 - Trinic CFRC Mix and Casting Materials (additional material funding below)

$500 - HDPE plastic sheet material for CNC weld + inflation testing + casting prototypes

$500 - Space protection, setup, and cleanup

$500 - Casting and mixing containers

$500 - Mixers for small batch concrete testing

$200 - Scales

$300 - Heavy-duty cart for moving materials and prototypes

$400 - Consumables (tape, mixers, welding irons, framing, markers, tubing, Teflon sheets, PPE)

Machines & Equipment: $4,500

$3,000 - Aluminum T-slot framing and connectors for CNC welding machine structure

$600 - Felt and ETFE sheets for CNC welding machine bed surface

$700 - Air compressor and fittings for GFRC spraying

$200 - Air pumps and hoses for inflation testing

Prototyping and Documentation $1,500

$250 - Hire students to set up and take down the Pop UP Drop Off for Upsate Art Week

$500 - Hire students to set up and take down the Pop UP Drop Off for the AHRA event

$250 - Hire students to set up and take down the Pop Up Drop Off for Earth Action Week

$500 - Hire students for InDesign content and documentation

Supplemental Funding Sources

Pratt Faculty Development Fund Grant 2022- Brackett $5,000

$3000 - Trinic GFRC casting materials and equipment

$1500 - GFRC mixing and casting equipment

$500 - Freight

d.r.a. Operating Budget - $2500

Funds from our research budget at the Center for Design Research in Architecture primarily go to supplying materials, equipment, and consumables for Advanced Design Research studios. These materials supplement the students' participation in the broader research topic of lightweight pneumatic formwork outside the lab.

d.r.a. Work Study/Research Assistant budget - $5,000

Research Assistant to develop comprehensive documentation and instructions for constructing a purpose-built CNC plastic welding machine for medium to large-scale pneumatic structures prototyping.

Research Assistant to study self-forming inflatable structures created using 2D welded patterns that deform into 3D structures under air pressure. The 2D to 3D transformation reduces fabrication complexity and facilitates more rapid CNC prototyping. The geometry principles involved parallel paper folding systems and created form-active structures through the surface tension of inflated membranes

Research Assistant time for installing the Pop Up Drop Off in Lexington, NY, and at two events on the Pratt Campus (AHRA and Earth Action Week

Events Sponsored by the ALNY & NYSCA Independet Project Grant 2023

2022, LexArtSci, Lexington House, Upstate Art Weekend 2022, Lexington, NY

2022, AHRA (Architectural Humanities and Research Association) Conference, Climate Collectivism, Pratt Institute Townhouses, Brooklyn, NY

2023, Earth Action Week, Pratt Institute Rose Garden, Brooklyn, NY

2023, Research Open House, Brooklyn Navy Yard, Pratt Institute Research Yard, Brooklyn, NY

2023, Pratt Undergraduate Architecture, Super Saturday - Distinguished Advanced Design Studio Jury

Project Gallery